MiniCEMS®

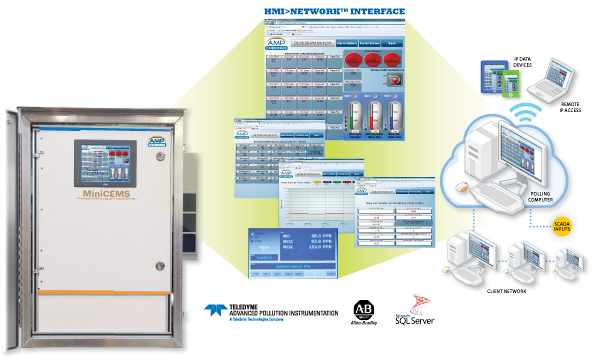

Ethernet/IP PLC-based DAS | HMI>Network Interface | Emissions Monitoring & Process Measurement

AMP-Cherokee’s MiniCEMS® is a self-contained, full-featured CEMS package for monitoring nitrogen oxides, sulfur dioxide, carbon monoxide, carbon dioxide, oxygen and opacity -- critical measurements for emissions compliance and process measurement of gas, oil and biomass-fired boilers and furnaces

The MiniCEMS® combines field-proven Teledyne-API T-Series analyzer benches with our open architecture DAS ProLogix data acquisition and reporting software. Our HMI>Network™ DAS Interface and Allen-Bradley PLCs control all facets of the CEMS and provide network and remote connectivity.

System and installation costs can be reduced by as much as 40% over a traditional CEMS.

Typical delivery of a MiniCEMS® to your site is from 8-10 weeks.

Open DAS Architecture.

Microsoft SQL Database.

SCADA Drag & Drop Development.

Through its open architecture, the ProLogix Data Acquisition System (DAS) collects emissions and process data and stores it in a Microsoft® SQL database. AMP-Cherokee’s unique CEMS HMI>Network™ DAS Interface provides distribution of data and reports to the client network and remote devices.

Data Redundancy.

Configurable Alarms.

The MiniCEMS® provides two levels of data redundancy. Data is continuously stored to both the onboard PLC and panel PC before it is sent to the client network. In the event of a loss of communication with the client network, data continues to be stored at the MiniCEMS®. When communications are reestablished, any data gaps are automatically updated on the client network.

Addressable locations on your network can be assigned to receive current status, scheduled reports and system alarms. Alarm utilities can be set to alert plant personnel via email and mobile devices -- on or off the network.

Easy Access. Simple Maintenance.

Our exclusive analyzer benches utilize simple power and sampling disconnects which allow the analyzers to slide in and out for easy maintenance and field servicing.

MiniCEMS® sample handling components are easily accessible - simply open the rear doors for waist-level access to service all sampling and conditioning equipment.

To prepare for your upcoming MACT requirements, AMP-Cherokee encourages you to develop a monitoring solution for your facility. For your convenience, we have prepared an online MiniCEMS®RFQ form to submit details on your compliance and process requirements.

Fill out the form above or contact AMP-Cherokee today at 800.399.4236 for a free consultation on your compliance monitoring and process performance needs.