Direct Extractive CEMS

Emissions Compliance & Process Performance

for Petrochemical, Industrial Boilers, Steel & Chemical Plants

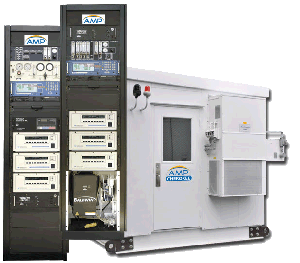

AMP-Cherokee provides direct-extractive

CEMS solutions that are ideally suited for utilities, boilers, FGD performance, SCR-NOx control, furnaces, gas turbines, process heaters, incinerators, and process controls. In addition to traditional CEMS

designed for maximum reliability and minimal maintenance in monitoring criteria pollutants, AMP-Cherokee can also accurately quantify exotic compounds through in-situ or extractive FTIR systems. AMP-Cherokee

compact Mini-CEMS® is designed for process monitoring and control

applications.

AMP-Cherokee CEM systems are easy to operate and can be configured to monitor for one or all of the following pollutants:

• NOx • SO2 • CO2 • O2 • CO • THC • Mercury • H2S • HCl & HF Acid

• NH3 • Particulate • Opacity • Volumetric Flow and Moisture

Ease of Operation & Maintenance

CEM systems from AMP-Cherokee are the easiest to maintain due to their

plug-and-play functional design and built-in sampling system redundancy.

Maintenance activities are only responsible for minimal CEM downtime

whenever the redundant sampling system is utilized.

Redundant Sampling Systems with Multiple Analyzers

AMP-Cherokee is the only CEM integrator to provide totally redundant

sampling systems as standard equipment. From the probe tip in the stack

to where the sample gas is introduced to the analyzers, AMP-Cherokee

provides the necessary connections for four gas analyzers (six are

available) as its standard CEM design.

Temporary CEM Systems & Gas Analyzers Rentals

AMP-Cherokee provides a variety of temporary CEMS for plant

backups and changeouts, pollutant characterization (PEMS) and

performance monitoring. We provide a turnkey solution for your specific

needs.

Fill out the form above or contact AMP-Cherokee today at 800.399.4236 for a free consultation on your compliance monitoring and process performance needs.